At Croxsons, we believe that to address the environmental challenges of our industry requires some profound changes. As an independent family business, we realise we can’t do everything, but we need to do something.

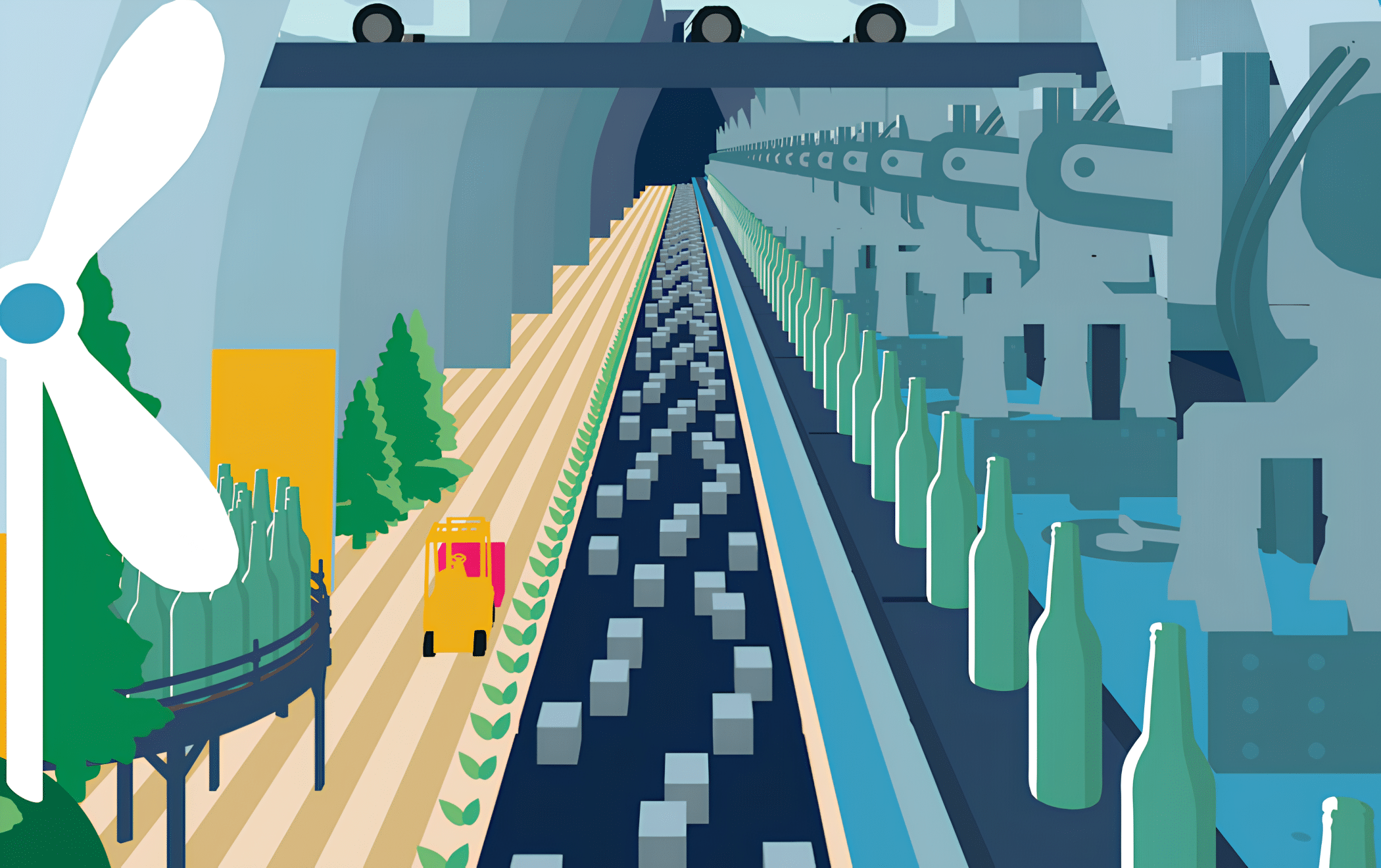

Decarbonising glass packaging will be a key part of the UK government’s commitment to reach net zero by 2050. We recognise that glass manufacturing is an energy intensive process but the future is looking clean – electricity, hydrogen and beyond.

Where existing furnaces traditionally use natural gas, we can already produce in furnaces utilising 100% electricity as the primary energy for melting, but we want to see this ability brought to the large scale production required by many of our customers. Plans are already developed and in-process to produce in furnaces powered by 100% renewable electricity, as well as furnaces utilising hydrogen. Having already trialled alternative fuels such as 100% biogas, we have delivered bottles with an estimated 99% reduction in carbon footprint, but with the same benchmarks for quality and performance.

As a fully recyclable product, with minimal impact to the environment once made, glass has a bright future. We are confident in the plans for and to help deliver ultra-low or no carbon solutions for our customers.

To mark our 150th anniversary in 2022, sustainability initiatives included funding the planting of 150,000 new trees during the year through environmental services company Ecologi.

Planting trees is proven to be one of the most effective tools to tackle the climate crisis, reportedly helping to undo over 30 years of carbon damage and keeping temperatures from rising above 1.5°C.

At the same time, we became involved with other projects that meet 11 of the UN’s sustainable development goals, addressing poverty, equality, economic growth and sustainable living with the oceans. As well as committing to reducing and offsetting the balance of our Scope 1, Scope 2 and Scope 3 emissions.

Today, glass is 30% lighter, 70% less energy-intensive and emits 50% less CO2 than fifty years ago. The glass packaging industry continuously invests in optimising energy use and switching to green and renewable energies – to reduce the overall environmental impacts and manufacturing costs.

Although recycling is less energy intensive than the production of glass packaging, the rate is still very high. That’s why the sector has united to meet the EU’s 2030 decarbonisation targets, electrifying its processes with a mix of 80% electricity and 20% gas in the “Furnace for the Future” pilot by the Ardagh Group.

By 2050, glass production aims to offer fully climate-neutral packaging solutions in addition to being fully circular.

Although glass can be recycled virtually infinitely, this doesn’t happen in every country. The cost implications of heavy glass include a greater amount of raw materials and energy to maintain a furnace at a constant temperature.

Lighter bottles are not only cheaper to make, but production volumes can also be increased. Right weighting the initial design helps to improve carbon usage and emissions from each bottle.

Drinks and their packaging are often produced in different locations, so transportation can be costly too, with protective packaging adding to the amount of fuel required. And as younger consumers are increasingly concerned with sustainability, this is why more producers are changing to lighter bottles to ensure an eco-friendly supply chain.

We can’t do everything, but we must do something. That’s why we’re offsetting the carbon footprint of every single employee, alongside completing our journey to become a carbon neutral business.

Independently examined and qualified, our offsets are gold standard yet still go further, hitting 15 of the 17 United Nations Sustainability Development Goals.

Moving to Sutton has also enabled staff and visitors to travel by train, cycle in or walk. And rather than constructing an entirely new office, we used the vacant shell of an historic building in the town centre.

Distribution contributes significantly to the carbon footprint of container glass, but our partner Encirc has identified rail as a potential solution to reducing emissions.

With its railhead currently delivering raw materials and recycled glass, the manufacturer plans to create an ultra-sustainable transport network for glass containers across the UK, with the ambition to have 70% of bottles eventually leaving its Cheshire site by rail.

According to Encirc, a tonne of freight transported by rail produces 76% fewer carbon emissions and each load is equivalent to taking 66 lorries off the road. This will significantly reduce the carbon footprint of every bottle across its full lifecycle, and the emissions passed onto the consumer.

Not every customer will have capacity to receive deliveries by train, however this will help avoid reliance on road haulage exclusively.

PCR stands for post-consumer recycled content. Reclaimed and crushed into cullet, it’s then mixed with the raw materials of glass (silica sand, sodium carbonate, calcium oxide derived from limestone, and lesser amounts of other minerals) in varying percentages, before being melted down and moulded into new products.

This ‘closed loop’ process can be repeated endlessly without damage to the end product – and the higher the percentage of PCR glass, the lower the environmental impact. The quality of the finished PCR product is assessed on colour, heavy metal content and dimensional stability/strength.

Croxsons is partnering with Estal on products using 100% PCR content, which will result in significant energy savings, less extraction of virgin raw materials, and lower CO2 emissions.